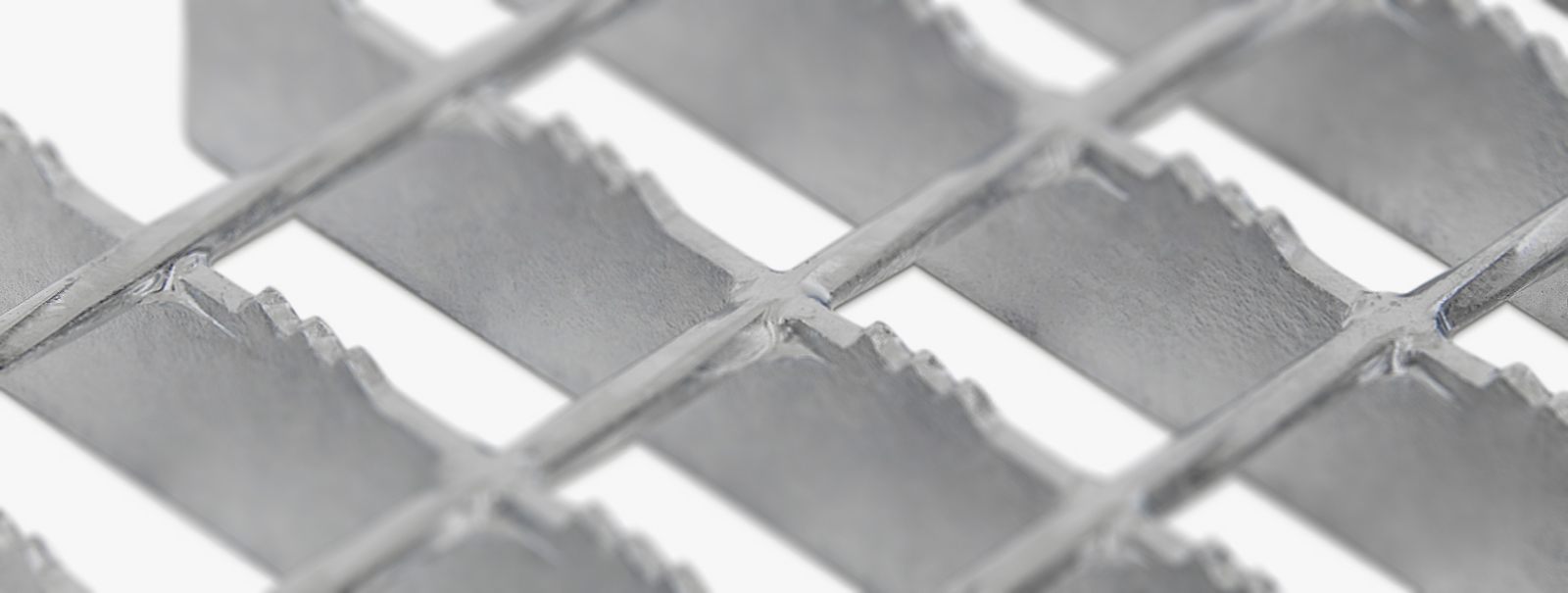

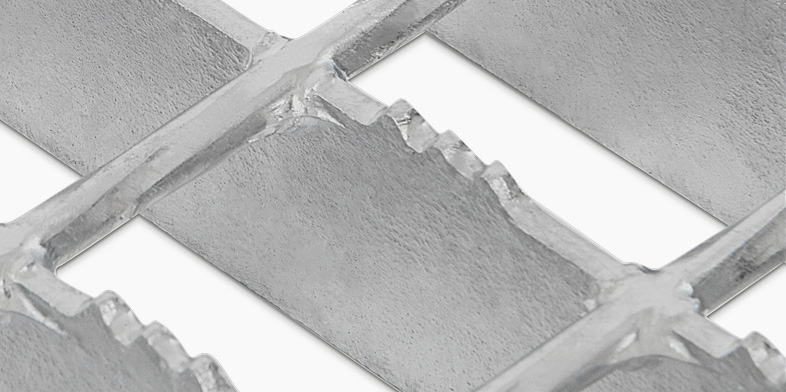

Electrowelded grating with discontinuous serrations

Grating with a non-slip surface, thanks to the discontinuous serrations on the bearing bars, which ensures a maximum anti-slip degree of R13.

Grating with a non-slip surface, thanks to the discontinuous serrations on the bearing bars, which ensures a maximum anti-slip degree of R13.

A electrowelded or electroforged grating consists of serrated intermittent teeth bearing bars and transversal rods joined by welding, without the use of added material, and by pressure concentrated on the joints, guaranteeing the joint at each intersection and the uniformity of the grating.

Various qualities of hot rolled carbon steel, is the most common material used in the manufacture of

electrowelded grating. The stresses to which it would be subjected determine the quality and finish, with the most recommended being galvanized, which provides the essential protection against corrosion. The stainless steel is another material in which can be used to make electrowelded steel gratings.

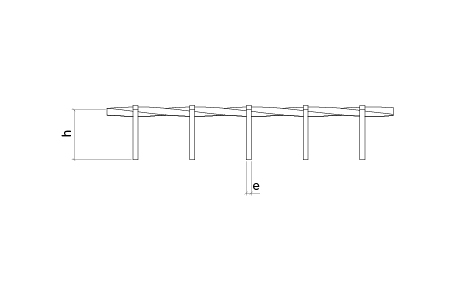

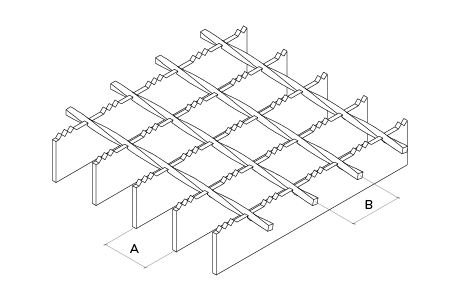

The pictures shown are type details whose measurements are set out in the Product Manufacturing Table.

Side view

Isometric view

The values shown in the tables are referenced to those included in the graphical representation of the product. AxB represents the distance between the axes of the bar (A) and (B) in millimetres, the distance between axes of the twisted square.

We want to be part and be an active provider of your project. Our staff will be happy to advise you to achieve all your goals.

Do you want to go back to view the full catalogue?