Most works require some kind of certificate, whether it be materials, manufacturing, installation or efficiency, among others. This means that it is increasingly important that construction companies or manufacturers have the maximum possible certifications, as this will allow them to reach the largest number of projects both nationally and internationally. In this post we will talk about NAAM MBG531 standard of the American National Standard and how it applies to metal grating.

Regulations tend to be increasingly homogeneous overall, but in each country or geographical area they have peculiarities that differentiate them from each other. If there is one thing clear, it is that a competitive advantage lies in having products or manufacturing methods that can meet different regulations at the same time and thus reduce manufacturing costs.

NAAM standard MBG531

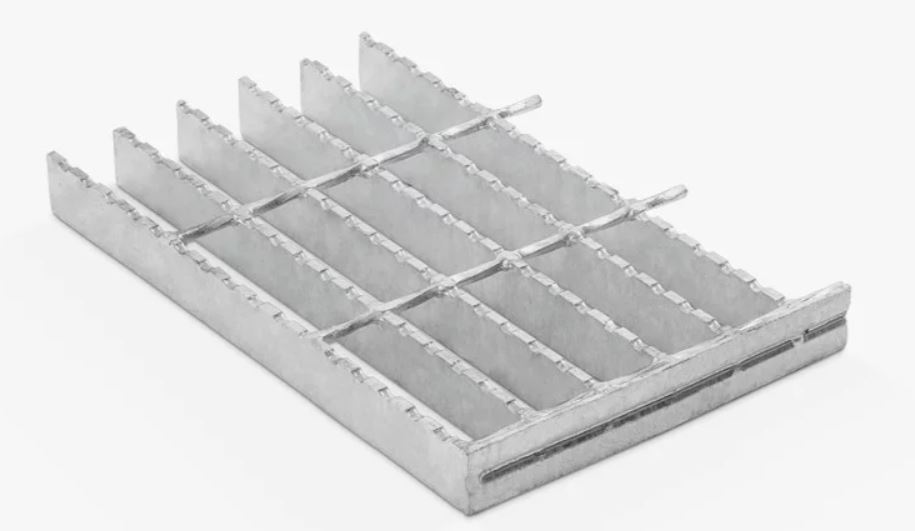

As we have already mentioned, we will comment on NAAM standard MBG531, which applies in the United States of America (it comes from that country) and is applied in surrounding countries, as is the case in Mexico. This regulation regulates the characteristics for the manufacture of metal grilles in both steel and aluminum as well as other aspects such as the installation of them as well as the realization of plans, among others.

How does this regulation affect grating?

The main section establishes the measures of the meshes as well as the height and thickness of the soleras and separators as well as the manufacturing tolerances of the same. In addition, it also regulates the loads by means of tables with theoretical calculations for the different types of gratings and materials with which they are manufactured. It also provides how ladder steps should be manufactured.

In short, this regulation is a kind of very explanatory guide on the parameters that grating must be manufactured to comply with. In addition to these points, other aspects are also mentioned such as the correct way to install grating on the structure, the different types of fasteners that can be used as well as the different applications that this product has. It also fixes the terms in question of making platform designs and to whom each part corresponds (between manufacturer and customer), also determining what is considered gross or manufacturing surface to obtain the net surface or with the required shape.

The rule ends with a glossary of terms that are mentioned throughout it and that clarifies the possible doubts that may arise when interpreting it.

Regulations in other countries

Around the world there are different regulations that involve choosing one type of grating or another. For example, in Spain there is a rule that in those places (platforms or stairs) where people are going to transit underneath, those platforms or stairs must prevent the passage of an 8mm sphere. The purpose of the same is to prevent objects from falling from one floor to another and can cause accidents. To give other examples, in France the regulations for similar situations mark the size of the sphere at 20mm.

Unlike the NAAM MBG531 standard, these two European standards that we have set as an example do not set many requirements as to the type of grating to be manufactured (mesh opening or height of screed) but requires that the passage of spheres of the above size be prevented.

What solution does Grupo Relesa offer?

In Grupo Relesa we manufacture according to the standards of this regulation and not only that, but we have a certificate from an external company that certifies that we meet all the requirements set in it. It should be remembered that at Grupo Relesa we advise all our customers, studying each situation individually and offering products adapted to different regulations and situations, as it is very important at present, especially when it comes to certification for certain projects.