When we talk about steel grating, we often have to mention the auxiliary elements or accessories that can go next to it, usually welded as the front non-slip or baseboards. Within that list we also find the bindings. These make the connection between the grating and the structure without the need for welding. Below we talk about the best fastening and joining clips for steel grating.

Steel grating can simply be supported on the structure, but with the clearances between them to avoid that with the expansion of the material or with the tolerances of manufacture these do not fit in the structure, grating does not usually fit millimetrically like a paved floor. Therefore, when you step on it there are movements and vibrations. If we want to reduce the level of vibrations, we must place joining clips. They allow the grating to offer much more safety when using them, generating more stability by reducing these vibrations.

How is steel grating placed?

Usually, grilles are placed in a horizontal position, resting on a metal structure formed by beams or in trenches or holes made with angular fences. Another scenario that we also find is that they support directly on the concrete, something not recommended. The other arrangement is that of fences or facades, in which the grilles are placed in a vertical position.

Types of fastening and joining clips for metal grating

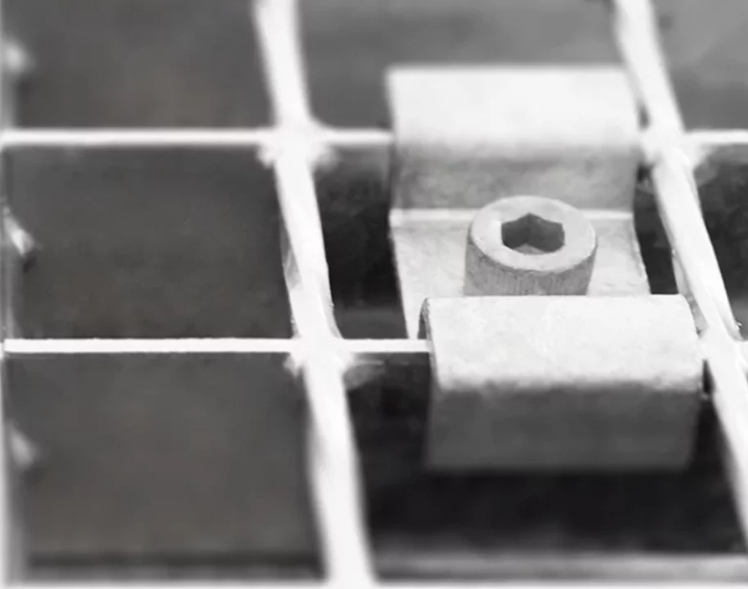

Fastening parts: Also known as staples, they are composed of a high “M” shaped part with a drill which is located between two grating plates, a low part that is fixed under the structure (either a beam or angular) and at the same time under the grating plates. The other elements are: the screw that is introduced by the upper part and the nut to tighten it, joining both upper and lower part to finally fix the frame to the structure. In this section we also find connecting parts that are placed between two gratings (not the structure), reinforcing and complementing the work of the bindings.

In “standard” fastening parts we also find other types for very thick mesh grilles, in which the upper part is not included because with the screw it is enough to hold the grille up as the distance between plates is very reduced. Another type is formed by a high disc-shaped part that acts as a stop, serving this piece for different types of meshes, a very versatile solution.

Self-tapping/self-locking screw: The self-tapping screws have the function of perforating the base material of support, being permanently fixed while the self-locking ones allow to reduce vibrations and consequently that the screws are not loosened with the movement. High “M” parts can be used to hold the grating.

Welded drilled plates: In this option, perforated metal sheets are welded into the grid to then place the screw and nut directly on site. This method is usually used in aesthetic finishes or suspended ceilings. The drawback is that the measurement to manufacture has to be accurate so that there are no problems with the slack and perfectly match the drill plate with that of the structure.

These are the most common cases, but what if we have to fix a fence?

In this type of installation in which the grilles are placed in a vertical position, the solution is to weld a long perforated plate from the grille itself to screw it to the intermediate posts. Depending on the height of the fence, more or less long plates will be placed to provide rigidity and stability to the fence. The posts are also made with a base plate for screwing or are directly embedded into the concrete wall.

In other cases such as grilles that are used for passing vehicles, we do not recommend fastening parts because they are not designed for those loads and can break, so the solution is to weld the grating to the structure or just leave them supported.

Regarding the number of parts to use and from the experience as manufacturers, we recommend as an indication four units per square meter or per grating, being six in the case that the surface of the grating is excessively large. In any case, it will be the end customer who decides the amount of bindings to be supplied.

For more information on the best fixings for metal grating, do not hesitate to contact us.