In recent years, a substitute for steel grating has appeared: plastic grating. In this post we will explain its main characteristics and in what situations it can replace metal grating.

What is plastic grating?

Fiberglass reinforced polyester:

- Polyester: Resin, which like many others, derives from petroleum and is obtained through a chemical process. The different types of resin that can be obtained from crude oil have multiple applications in the industry.

- Fiberglass: Material based on silicon dioxide and with a thread-like appearance. In addition to being used as an insulating material, it is also used in polymeric products as a reinforcement agent.

- Reinforced: This term refers to the process by which fiberglass is joined with polyester, giving the final product strength and higher quality.

These three elements perfectly define the characteristics of plastic grating. We can also find this product with the acronym “GRP” (Glass reinforced plastic) or in a more everyday language, plastic or polyester grating.

Gratings and many other products are manufactured with these petroleum products. In the industry such materials are used for their cost, polyvalence and efficiency as they have multiple advantages over others that have been used throughout history. As an example we can mention the automotive industry, where elements such as carbon or different polymers have more and more prominence in components manufacture. This change occurs because with these elements you get stronger parts, higher quality or significantly reduce costs (some can be manufactured in 3D printers) and enters into the constant evolution of the industry to create more efficient products.

Plastic grating manufacture

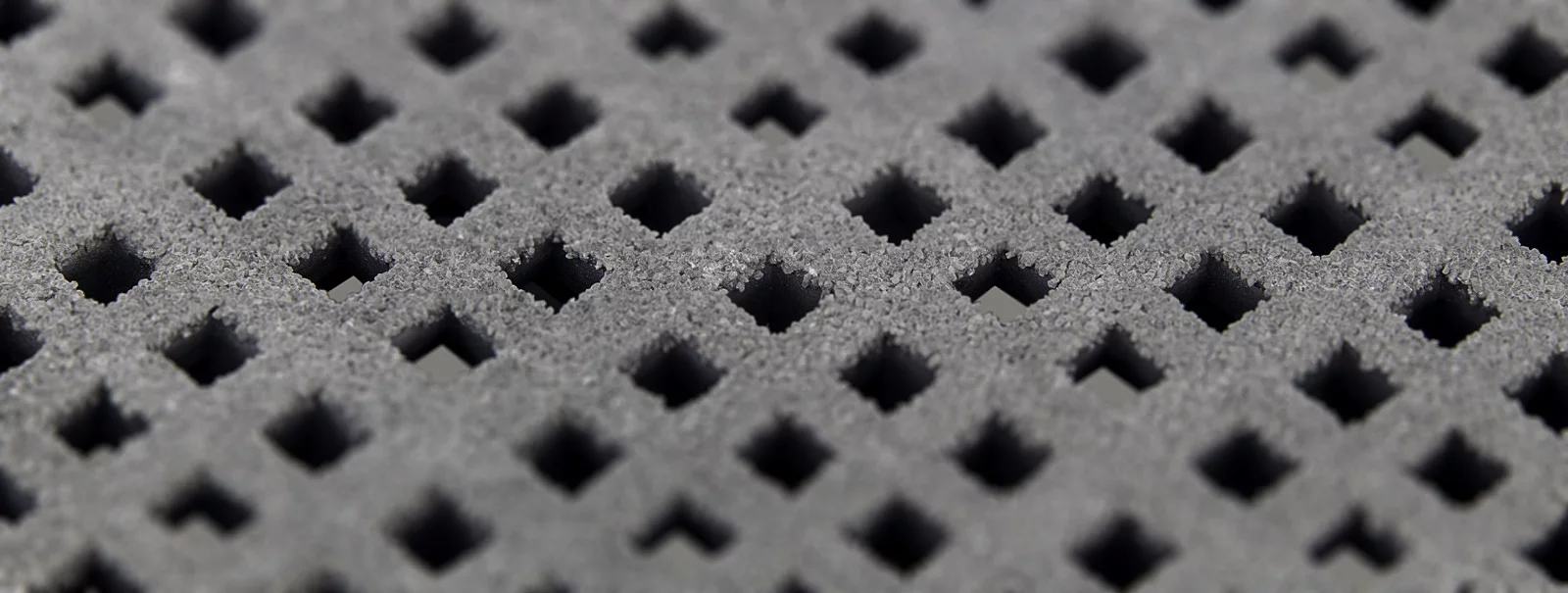

Plastic grating is manufactured in prefabricated moulding tables with the shape that is intended to be given to each module. Due to this manufacturing methodology, a uniform block with bidirectional resistance is obtained on each part of grating. Once finished, they can be cut to offer a tailor-made product with the required shape.

Advantages

One of the great advantages of plastic grating is undoubtedly its corrosion resistance and to many of the chemical agents as well as to salinity. This is a good thing for its use in certain industries or where these chemical agents are found as well as in coastal areas.

Another point we have to mention is that it is self-extinguishing, a prerequisite for certain facilities to comply with current legislation. Besides, it doesn’t conduct electricity.

Finally, in loading terms it has an advantage derived from the way in which it is manufactured, and this is that it supports the load bidirectionally as it is a uniform block where both plates are resistant. This avoids possible assembly errors with the placement of the grilles on the supports and it should be added that when the plastic grating is cut it doesn´t lose its resistance capacity.

Disadvantages

One of the main disadvantages of plastic grating is that its components are not recyclable, unlike steel which can be reused almost infinitely. In a context where we are increasingly familiar with terms like carbon footprint or global warming, among others, the use of non-recyclable or polluting materials can pose a problem regarding the companies social responsibility and therefore their assessment or external perception, in addition to the pollution itself that is generated and its consequences. All this is accentuated in a context where actions to reduce emissions, consumption and pollution at the company level are increasingly important.

Another disadvantage is the type of resin that makes up the grating, since there are different and each one has some properties that depending on the application that is intended to give, it can be used or not. It is more a matter of having clear the type of product that is being purchased.

Plastic grating applications

As we have already mentioned, plastic is not only used for grating, but we can find pipes, railings, log covers and even beams. Within their uses and observing their characteristics, the most common are corrosive environments such as ships or water treatment plants, whether on platforms, floors or stairs.

Types of plastic grating

As with the metal grating, plastic grating is also manufactured with different meshes or heights both to meet regulations or load requirements. We also find “blind” plastic grating, a grid completely covered by a sheet that makes it opaque and within the different types, we find sandblasted and tearing, the choice of one and the other will depend on the slip risk.

When does plastic grating replace metal grating

After all of the above and by way of conclusion, we can say that plastic grating replaces metal grating for those situations in which the environment to which it is going to be exposed is highly corrosive and the galvanizing is not a sufficiently durable protection or the option of stainless steel grating increases the cost too much. In short, the choice of plastic or metal grating will depend on the use and needs that are required which will make one or the other more suitable.